Daikin offers innovative solutions to your problems and contribute to the realization of a sustainable society

AKZ & AKJ oil cooling units

AKW water chilling units

Improved energy-saving inverter Oil & Water Cooling Unit using Daikin core inverter control technology from air conditioner technology

Benefits

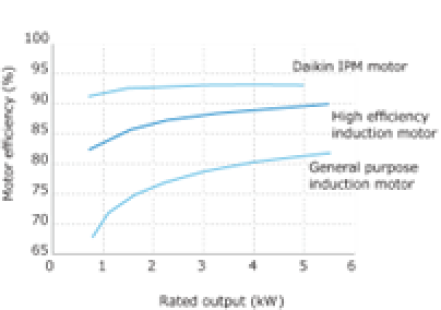

- High Energy-Saving performance

- Compact Design – smallest size in the industry

- Low Noise level 58dB(A)

- High Accuracy Temperature Control of +- 0.1C

- Higher Durability

Special Features

- New Refrigerant R410A protect ozone layer

- Our engineering team can replace your old coolers with Daikin units perfectly

- We keep stock for most of the cooling units & spare parts

Chillers make cold water or water/glycol fluid mixture to cool buildings or processes. Often used in conjunction with coils in air handlers, chillers receive warm fluid from the air handler coil or process load, lower the temperature of the fluid, then a pump returns the fluid to the air handler coil or process. Chillers come in two main varieties: air-cooled and water-cooled. An air cooled chiller rejects the heat absorbed from the building or process directly to the outdoor air using refrigerant to air coils and fans that blow outdoor air directly over those coils. A water cooled chiller rejects the absorbed heat to an additional fluid loop that can then reject the heat through a secondary device such as a cooling tower (more common) or dry cooler (less common).

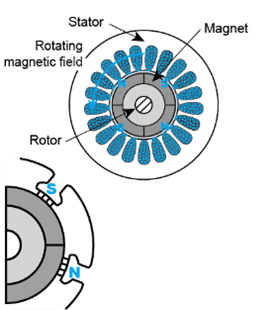

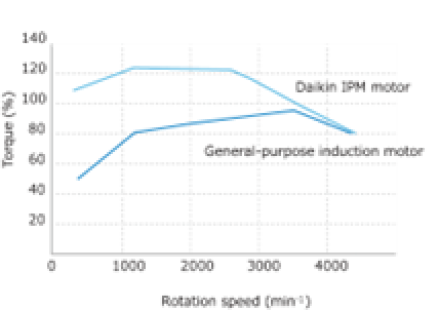

High torque at a low-speed range

Daikin IPM motors produce high torque at a low speed. Generally, an inverter type may have limited torque when set at a low-speed range, but Daikin IPM motors can work around this technicality.

The magnetic field lines at the south pole side are longer than the north side. Similar to how a stretched rubber band contracts, the magnetic field lines at the south pole will try to shorten. As a result, a rotational force will occur due to the reluctance torque moving in a counterclockwise direction (see the arrow in the illustration).